Innovative Solutions for Boosting Shrimp Farming Productivity

Key benefits:

- Up to two times improvement in shrimp production.

- Significant decrease in shrimp mortality.

- Minimal or no use of pharmaceuticals and chemicals.

- Significant improvement in shrimp weight.

- 30% less time to bigger weight than shrimp raised in normal water.

Introduction

Over half of crustacean consumption is produced through aquaculture.

As efforts continue to meet increasing global demand whilst maintaining quality, a lack of dissolved oxygen in shrimp ponds is proving a key obstacle in achieving these demands cost effectively, if at all.

Increasing stock density is a direct way for farmers to meet these demands, however, with every additional shrimp in a fixed water volume needing more oxygen to breathe a shortage of dissolved oxygen is inevitable.

Furthermore, additional waste byproduct accumulates on pond beds which also consumes oxygen leading to damage to the ecosystem of plants also necessary for optimal water and shrimp health.

Our technology can alleviate these problems by rapidly elevating and maintaining higher levels of dissolved oxygen levels in the farm and effectively oxygenating the entire water column – bed to surface.

The solution

Custom Fluids’ innovative solution solves many inherent problems associated with shrimp farming operations in an effective and efficient way.

The feeding of shrimp stock and subsequent waste, foul pens or ponds, resulting in lower oxygen levels and subsequent reduced yields.

Feed and waste byproducts result in reduced oxygen levels denying it for the stock. The Custom Fluids solution provides the means to raise and control oxygen levels and increases yields, productivity whilst decreasing costs.

Our ultra-fine bubble technology allows the shrimp farming industry to make economically viable choices to treat and maintain their water systems.

Ultra-fine bubbles (or better known as nano bubbles) have a diameter less than 100 micrometers.

This gives them characteristics that ordinary, micro or macro bubbles don’t possess. Such as buoyancy, enabling them to oxygenate the entire water column and longevity due to their surface strength. All whilst little to no effect on total gas pressure.

These characteristics delivers an effective means to clean organic and inorganic pollutants in the water column and sediments.

As shrimp health and metabolic rates are affected by the concentration of oxygen in a rearing environment suppressed dissolved oxygen levels leads to decreased respiration and feeding activity that slows down growth rates. It can also lead to disease and fungal infections that can wipe out percentages of stock.

If correctly applied, oxygen supplementation ensures that shrimp farmers can achieve the highest possible survival rates under optimum breeding conditions to boost yields and profits.

Production Benefits

In trials and in production environments, oxygenated water using nano bubbles doubled production of shrimp while decreasing mortality up to 8 times with little to no use of pharmaceuticals or chemicals.

Furthermore, shrimp raised were up to 40% heavier in up to 30% less time than shrimpraised in normal water.

Energy Efficiency and ECO Value Benefits

Traditional aeration methods, such as paddle wheels, are very inefficient, leading to high energy costs to achieve desired dissolved oxygen levels.

Many traditional aeration technologies achieve less than 40% oxygen to water transfer ratio’s. That is, over half of the consumed energy is used to put air back into the atmosphere and not into the water.

Our technology delivers oxygen to water transfer rates of over 85%. This equates to significant reductions in energy consumption.

Furthermore, our unique systems engineering philosophy has allowed us to integrate the most energy efficient subsystems to create the smallest energy footprint per milligram of oxygen absorbed by the water compared to conventional aeration technologies.

These factors further contribute to reduced costs and improved profitability of shrimpfarms

Stock Density Benefits

Metabolic rates of shrimp can be severely affected by oxygen concentration levels in the water. Low dissolved oxygen levels decrease respiration and feeding activity subsequently slowing growth rates. Typically, dissolved oxygen levels exceeding 80% are ideal conditions is shrimp aquaculture.

Our Oxygenation technology ensures farmers can achieve high stocking densities whilst reducing the risk of mortality.

Disease Prevention Benefits

Lack of dissolved oxygen reduces the biological breakdown of shrimp waste on pond beds. This creates ideal conditions for bacteria and fungus to thrive, which subsequently risk disease and mortality in the shrimp.

This is typically dealt with using pharmaceuticals (antibiotics, vaccination and chemicals) causing stress to shrimp. Furthermore these bacteria and fungus accelerate deoxygenation in the water.

Our technology uses the natural properties of sufficiently oxygenated water to promote a balanced ecosystem and subsequent shrimp health.

Government Fisheries Dissolved Oxygen Trials

The Custom Fluids system produces trillions of neutrally buoyant, negatively charged Ultrafine Bubbles (nano-bubbles) that are 100nm or smaller in diameter.

These properties the bubbles stay suspended in water for long periods of time, efficiently mixing throughout the entire body of water and transferring oxygen at least 85% efficiency.

As the bubbles burst over time, Oxygen is made available and transferred to the water. The bubbles transfer oxygen at any depth and survive in solution for weeks, even in warm temperatures.

The system is an energy efficient, chemical free and environmentally friendly solution to raise Dissolved Oxygen levels in water bodies.

The trial

The trial

Custom Fluids recently carried out a Water Oxygenation trial at a Government Fisheries in Australia.

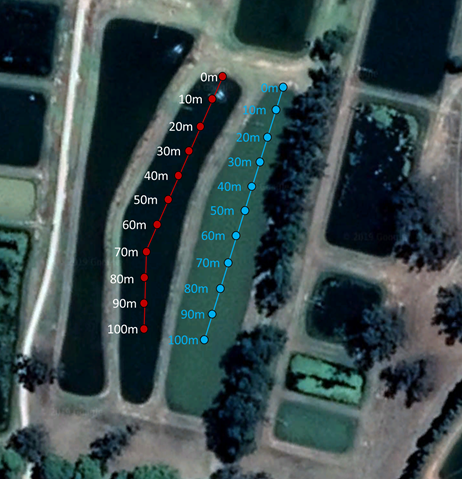

The trial involved 2 ponds, both approximately 100m x 15m x 1.6m equating to approximately 2.4 Mega-litres. The first pond (right pond in image) was the Oxygenated trial whilst the other (left pond in image) was a control pond with a conventional and commonly used aeration system that mixes air (not Oxygen) and water.

The Custom Fluids system was installed in the open near the trial pond and required only two 240 Volts sources to operate. The system worked with a fixed flow rate of approximately 350 litres per minute drawing water from the trial pond itself.

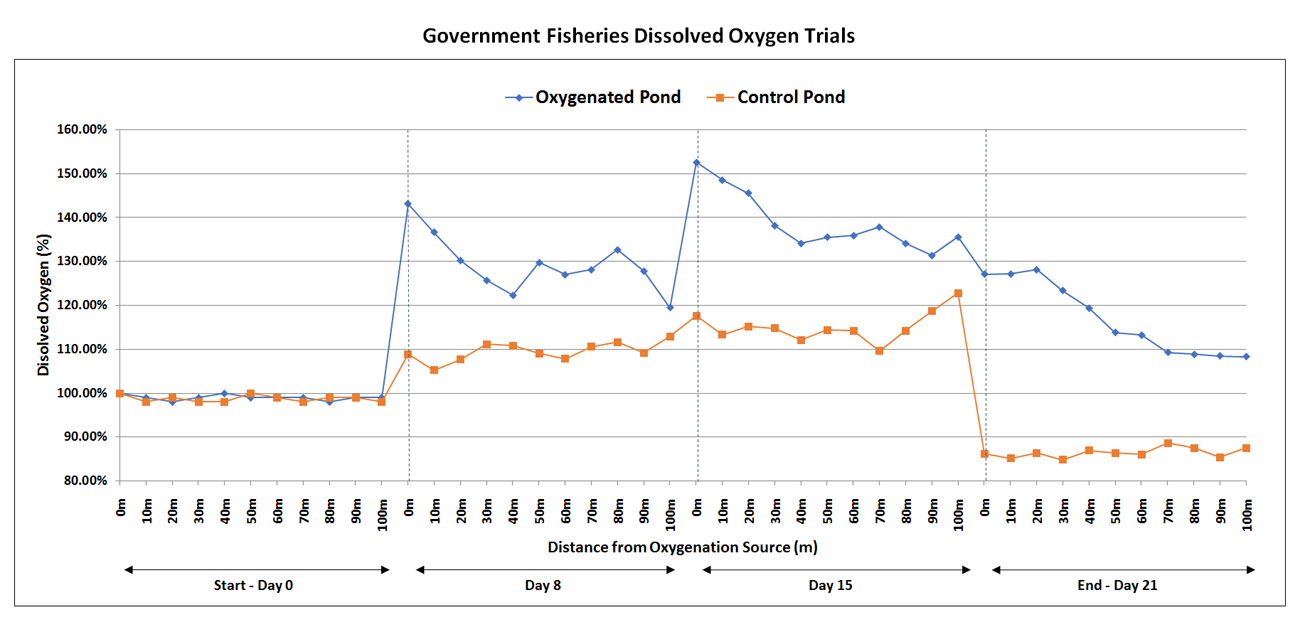

The results below show Dissolved Oxygen levels over the 21 days the trial was carried out. The data points are plotted in four sections covering the days the dissolved Oxygen were measured. Each section has 10 data points representing each 10 metres distance from the source of Oxygenation.

Key Facts and Benefits

Client: Government Fisheries

Pond Dimension: Approx. 100m x 15m x 1.6m

Pond Volume: Approx. 2.4 Mega-litres

Application: Raise Dissolved Oxygen Levels

System Flowrate: 350 LPM

Key Benefits:

- Peak Dissolved Oxygen level in the trial pond reached 153% at day 15 whilst the control achieved 118% in the same time.

- Within 46 hours, Dissolved Oxygen levels exceeded the control pond by 20%

- Maximum Dissolved Oxygen levels reached 45% reached 10m from source

- Peak Dissolved Oxygen levels across the entire pond 30% above the control pond

- Total Gas Pressure (TGP) remained consistent with the control pond throughout the trial and remained well within US EPA levels.

- At the furthest distance (100m) from the Oxygenation source, 22% above the control pond was achieved.

- After both systems were powered down, the trial pond remained 30% above (average) the control pond

Client remark: “The impact of the aerator across the entire pond is very evident….. The minimum readings of the aerated ponds in most cases exceed the maximum readings in the control pond.”